How to make a Patchwork Ring Band

Although this Patchwork Ring Band is one of my older designs back from around 2013/ 2014, I figured I would share how I make these rings as I do still get orders for them occasionally….This step by step is how I made 2 of these rings not too long ago. The couple I made them for wanted new matching wedding bands after one was lost and the other no longer fit.

Step 1. Cut the metal

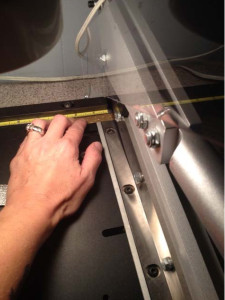

The first step is to figure out what size you want to make the ring and how long the silver needs to be so that you end up with a ring that is the size you need. There are all kinds of tools and charts online that you can use to figure this out. I suggest looking into it and see which item works best for you. Here is an example of chart that I came across when I Googled it real quick but there are plenty of options out there so make sure to take a look around to find what works best for you.

Step 2. Stamp the band

I always stamp my makers mark on my pieces along with “.925” so that people know it is made of sterling silver. I do this before I curve the band as my makers mark needs to be stamped onto a flat surface.

Step 3. Cut the little pieces to size

I always have a bunch of textured little pieces of metal laying around my studio. I roll print, etch, stamp and reticulate things on a regular basis so there are always little leftover bits. I save them for when I need to use them for something like this. You do not need to use textured pieces of metal for this step. I do because for one, it’s my style and two, I have them so why not put them to good use! I cut them into small pieces and lay them out on the silver I cut in step 1. The should fit together like puzzle… nice and tight with no spaces in between.

I play around with the pattern and color placement until I get something that I like.

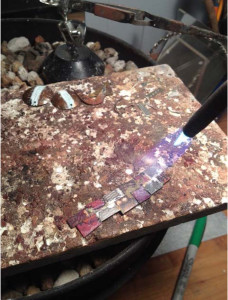

Step 4. Solder all of the little pieces

Please excuse my very well loved soldering pad in the next few photos…. I know it is a little bit hard to see what is going on here but I will try to explain.

After you have your pattern laid out in step 3, take all the little pieces one at a time and lay them on your soldering pad keeping them in some sort order so you know which piece goes where. Flip them over on the soldering pad so that the right side is facing down. Flux each piece and pre-melt solder onto the back of each piece. Wait for them to air cool a little bit. It is a lot easier to place the pieces when they are cooled down than it is when they are hot, so I always let them air cool before I actually solder them to the ring band.

Once they air cool you can flip them over and use your fingers to line them all up if you need to. I can’t believe I have to say this but here goes….DO NOT PICK UP HOT METAL WITH YOUR FINGERS!!! Wait for the metal to cool off first! I do not want to be responsible for you burning yourself so please make sure you do not pick up hot metal unless you use tweezers or pliers, etc.

Once you have the pieces all in place you can solder them to the ring band. It is easier to solder them all at once than it is to solder them one at a time.

Once you have all the pieces soldered on, quench, pickle and clean as usual.

Step 5. Make all the edges straight

Before shaping the ring make sure all 4 sides of the ring are straight. If you have any of the little pieces hanging over the edge cut them off now. Then check the edges that are going to be soldered together to close the “circle”. Make sure they are straight and parallel to each other. You can cut them with a bench shear or a saw, or file them, whichever works for you, but this is a very important step. If the edges do not meet properly there will be a gap in your solder seam. This could cause the solder to flow where you do not want it too and it can cause a very messy solder seam making your ring look not so nice. If there is texture on the outside of they ring you can kiss it goodbye if the solder gets on it.

Step 6. Shape the ring

The next step is to shape your Patchwork Ring Band. There are many ways to do this. You can use a ring bender or ring bending pliers, I use a ring mandrel and a rawhide mallet. I hammer on the band until the ends line up perfectly with each other. Once they do, I am ready to solder.

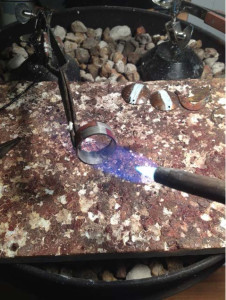

Step 7. Solder the ends together

You want to make sure that your ring does not roll away when you soldering it. I use locking tweezers in a third arm to hold the ring when I solder. The tweezers hold the ring in place and if I need to tilt or adjust the ring for any reason it is easy to do without too much trouble. After the ring is situated so it won’t roll, solder the ends together. I place my solder on the inside of the band so in case it melts all over it does not make a mess on the outside of the ring ruining the texture. After it is soldered I quench and pickle it.

Step 8. Clean up the edges

Once your ring is soldered and the fire scale is removed in the pickle it is time to start cleaning up the edges of the ring. I file the inside of the band with a round file and the outside edge with a flat file to round out and smooth out the rough edges so it is comfortable to wear.

Step 9. Oxidize the ring

You do not need to do this step if you want a shiny Patchwork Ring Band. Since I use a lot of texture I like to oxidize my pieces to bring out the detail in the texture. I use liver of sulfur (LOS) to oxidize my pieces. If you choose to do this step, please follow the directions on the package of whatever kind of oxidation solution you may choose to use.

Step 10. Remove oxidation from raised areas

If you did not oxidize your piece you can skip this step.

I only want my oxidization in the recesses of my pieces so I buff the oxidation off of the areas where I do not want it. There are many ways to do this as well. Here I am using pumice and water to remove the LOS from the raised areas but most of the time I use an abrasive brush in my flex shaft. It is faster and easier when I do bunches at a time, but since I was only making 2 rings here I chose to use pumice.

Step 11. Rinse and polish

Before I polish the ring I give it a quick rinse in the sink just to make sure there is no pumice or other foreign material on it before I polish it. Then I throw it in my tumbler for a bit to polish it and make it nice and shiny.

All done!

And there you have it! Done and all ready to be shipped out! I hope they like their new wedding rings!

To have a Patchwork Ring Band custom made just for you… or for you and your spouse as alternative wedding rings like this couple did, you can contact me

Also don’t forget to check out all of my latest pieces on my website here. All of the new items I make are listed on my website first before they hit my etsy shop. And if you really want to see more into my #jewelerslife make sure to follow me on Instagram here. Not only will you see more on how I do what I do, but you can also see a little bit more into my life and my studio, get sneak peaks of what I am working on and get a glimpse of the shenanigans of my fur babies, Django and Spotty! And if you have gotten this far… Thanks so much for following along! ~ Michele